|

Designing Compressed Air System

Compressed

air treatment, compressed air production Compressed

air treatment, compressed air production

Designing a compressed air system

Size considerations

Installation costs

Installation instructions

Variables to consider

Energy savings

System Configuration

Corrosion

Durable protection of equipment

Air contamination

Air leaks

Designing a Compressed Air System

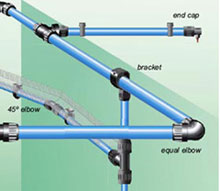

The Transair Connection Process

Labor accounts for 20 percent of the cost of

installing an aluminum piping system. By

comparison, labor accounts for 60 to 80 percent

of a steel system, 50 to 70 percent of a copper

system and 40 to 60 percent of a plastic system.

The

materials and modular design of a Transair air

quick connection pipe system makes it easier and

less expensive to install than traditional

systems. Its aluminum piping is easier to lift

and handle than standard steel piping, and its

push-to-connect fittings secure connections with

a simple push and twist. The fittings eliminate

the need for special tools, pipe preparation and

threading. The use of Transair also eliminates

the time needed for soldering and glue drying.

And once the pipe is pushed into the fittings,

the connections secure and ready to be

pressurized.

Size Considerations

A common error we see in compressed air systems,

in addition to poor piping practice, is line

sizes too small for the desired air flow. This

isnít limited to the interconnecting piping from

compressor discharge to dryer to header. It also

applies to the distribution lines conveying air

to production areas and within the equipment

found there. Undersized piping restricts the

flow and reduces the discharge pressure, thereby

robbing the user of expensive compressed air

power. Small piping exacerbates poor piping

practices by increasing velocity- and

turbulence-induced backpressure.

Pipe size and layout design are the most

important variables in moving air from the

compressor to the point of use. Poor systems not

only consume significant energy dollars, but

also degrade productivity and quality. The

objective in sizing interconnecting piping is to

transport the maximum expected volumetric flow

from the compressor discharge, through the

dryers, filters and receivers, to the main

distribution header with minimum pressure drop.

Contemporary designs that consider the true cost

of compressed air target a total pressure drop

of less than 3 psi.

Beyond this point, the objective for the main

header is to transport the maximum anticipated

flow to the production area and provide an

acceptable supply volume for drops or feeder

lines. Again, modern designs consider an

acceptable header pressure drop to be 0 psi.

Finally, for the drops or feeder lines, the

objective is to deliver the maximum anticipated

flow to the work station or process with minimum

or no pressure loss. Again, the line size should

be sized for near zero loss. The lower the

pressure drop in transporting air, the lower the

systemís energy input.

^ Back To Top

Installation Costs

Transair compressed air pipe systems are quick

to install and ready for immediate

pressurization. No particular preparation

(cutting, deburring, chamfering, etc.) is

required. Transair aluminum pipe is calibrated

and fits perfectly with all Transair components.

Each connection is automatically secured and the

seal is optimized. Components are removable and

interchangeable and allow immediate and easy

layout modifications. All components incorporate

quick assembly connection that enables Transair

systems to be assembled much more quickly than

galvanized steel or copper system.

Example:

Galvanized installation: 6 feet per hour

Copper installation: 8 feet per hour

Transair installation: 45 feet per hour

All modifications add extensions to Transair

systems can be done extremely quickly and will

meet your production requirements.

Example:

Lateral dismantling of pipe: 1 minutes 30

seconds

Drilling of pipe: 2 minutes 30 seconds

Mounting Brackets: 45 seconds

Remounting of pipe to the system: 1 minute 30

seconds

Installation Instructions

General:

Prior to the installation of a Transair

compressed air distribution system, the

installer should ensure that the installation

area complies with any regulations applicable to

areas exposed to explosive hazards (in

particular the effect of static electricity in a

silo area). Transair should be installed

downstream of the compressed air receiver, or

after the dryer. Flexible Transair hose can be

installed at the start of the system in order to

eliminate any sources of vibration and to

facilitate maintenance operations. When

maintaining or modifying a Transair system, the

relevant section should be vented prior to the

commencement of any work. Installers should use

only Transair components and accessories, in

particular Transair pipe clips and fixture

clamps. The technical properties of the Transair

components, as described in the Transair

catalog, must be respected.

Commissioning the Installation

Once the Transair installation has been

installed and prior to pressurizing, the

installer should complete all tests, inspections

and compliance checks as stated in any contract

and according to sound engineering practice and

current local regulations.

Transair Pipe and Hoses

Transair pipe should be protected from

mechanical impact, particularly if exposed to

collision with fork-lift trucks or when sited in

an environment with moving overhead loads.

Similarly, rotation of the pipe and pipe

supports should be avoided. Transair pipe must

not be welded. Flexible Transair hoses should be

used in accordance with the recommendations of

the installation guidelines. Note: In certain

situations, Transair aluminium pipe may be

formed with a bend - please contact us for

further information.

Expansion / Contraction

Expansion and contraction of the system should

be calculated prior to installation. The system

designer and installer should calculate the

elongation or retraction of each Transair line

according to the recommendations in this

installation guide.

^ Back To Top

Component Assembly

Transair components are provided with assembly

instructions for their correct use - simply

follow the methods and recommendations stated in

this document.

Situations to Avoid:

Installation within a solid mass (concrete,

foam, etc.)

The hanging of any external equipment to

Transair pipe

The use of Transair for earthing, or as a

support for electrical equipment

Exposure to chemicals that are incompatible with

Transair components (please contact us for

further details)

Variables to consider

^ Back To Top

Successful operations need to be able to take

advantage of new equipment options and

automation techniques without incurring lengthy

downtime and expense. Consequently, the ability

to reconfigure production layouts or implement

process changes quickly is critical. Transair

makes reconfiguration practical and efficient.

Because Transairís fittings are not soldered or

glued, the components are reusable and can be

removed and reinstalled. The modular design and

handling ease enable plant personnel to

implement many layout changes within minutes,

not hours. This minimizes downtime and increases

plant productivity. Furthermore, the flexible

hose used in a Transair pipe system eliminates

many of the layout constraints encountered with

rigid piping systems such as physical obstacles.

Energy savings

^ Back To Top

Energy costs associated with a compressed air

system are significant. For example, when

analyzed over a ten-year period, the cost of

energy consumed by an average compressed air

system exceeded other costs, including the

initial cost of equipment and installation. The

cost of electric may exceed the cost of the

capital equipment, each year! System pressure

drops are one cause of inefficient energy use. A

14.5 psi pressure drop uses 10 percent

additional energy. These drops can result from a

number of sources, including poor system

configuration, interior pipe surface corrosion,

and compressed air contamination.

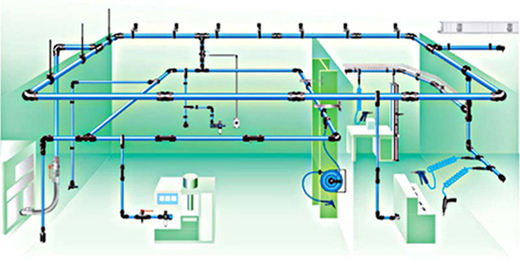

System configuration

^ Back To Top

Poor system configuration can lead to improper

airflow. The flexible hose used in Transair

aluminum piping system eliminates many of the

layout constraints encountered with rigid piping

systems. It accommodates physical obstacles and

provides a link between the compressor and

piping.

Corrosion ^ Back To Top

Interior pipe corrosion is a common cause of

pressure drops and higher maintenance costs.

Smooth bore piping, such as plastic and

aluminum, resist corrosion. Galvanized and black

iron pipe decreases in opening over time.

Galvanized and black iron fittings are crudely

designed with restrictions to air flow

internally. Brass and copper fittings and valves

typically have smaller bores than the associated

pipe size. Transair pipe will not corrode and

the fittings are ALL designed for compressed air

flow with full bore construction.

Durability of equipment

^ Back To Top

Transair enables elimination of the problem of

rust, usually associated with steel air pipe

systems. It guarantees the complete absence of

corrosion (self protection by formation of

aluminum oxide). The inner surface of aluminum

pipe ensures good and constant quality clean air

continuously.

Legris Transair also protects industrial

equipment against water deterioration thanks to

its quick assembly brackets with integral upward

loop.

Compressing ambient air to the discharge

pressure introduces moisture into supplied air.

Unfortunately, aftercoolers, filters, and dryers

do not completely eliminate moisture and its

destructive results. As a result, steel pipe

systems will begin to rust and corrode, thereby

inhibiting smooth airflow and reducing system

pressure.

Pipe corrosion also increases compressed air

system maintenance. Steel pipe systems need to

be dismantled and inspected to monitor corrosion

build up. Not only does replacing corroded pipe

interfere with production, it causes rust,

corrosion and other particles to be released

into the air system, thereby causing instrument,

valve, tool and machine operation problems or

damage with the resultant downtime.

Air contamination

^ Back To Top

Air cleanliness is another factor that affects

consistent airflow. Dirt and dust particles

passing through the piping system are gradually

deposited on the interior surface of piping. As

these deposits accumulate, friction increases

and system pressure decreases. Black iron and

galvanized steel piping systems are more prone

to build-up than stainless steel. Meanwhile,

smooth bore piping materials, such as Transair

aluminum pipe, offer more resistance to deposit

build-ups.

Air leaks ^ Back To Top

Inherent in threaded steel piping systems, non

productive leaks also waste compressed air, thus

electrical energy and your dollars. Difficult to

trace and repair, they can have a huge impact on

operating budgets. A typical threaded compressed

air system leaks 35% of its volume, thatís one

third of the electrical bill associated with

compressed air! With its bubble-tight seals,

pipe and push to connect fittings will eliminate

compressed air leaks and lower your electrical

costs associated with the production of

compressed air.

Improving productivity while reducing operating

costs is a goal shared by nearly every

manufacturing plant. You cannot buy compressed

air, you must produce it. The initial capital

cost of a compressed air system is minor

compared to the operational cost. A Transair

aluminum and stainless steel pipe system will

significantly reduce your operational cost!

Transair aluminum piping system offers virtually

leak-free performance. Legris Transair

guarantees the Transair pipe system to be free

of leaks for two (2) years. The Transair

aluminum pipe and push to connect fittings will

eliminate compressed air leaks and lower your

electrical costs associated with the production

of compressed air.

|